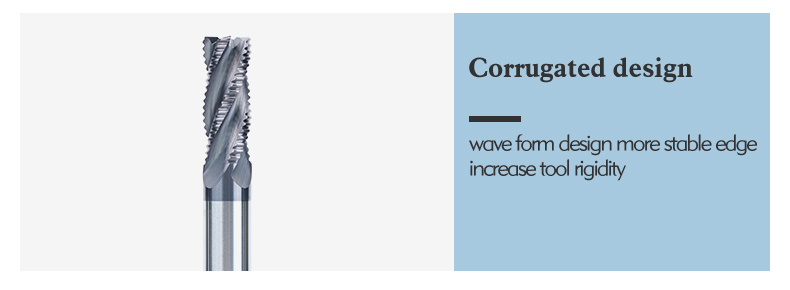

Tungsten Carbide roughing End Mill

Features

Carbide roughing end mill ine akati wandei anoonekwa maficha:

1. Izvi zvigayo zvekupedzisira zvakagadzirirwa kuti zvinyatso bvisa zvinhu panguva ye roughing, zvichiita kuti zvive zvakakodzera machining e-high-speed uye kubvisa zvinhu zvinorema.

2. Yakagadzirwa nemhando yepamusoro tungsten carbide, zvigayo izvi zvinopa kuomarara kwepamusoro uye kusimba kutsungirira kuomarara kwekushandisa rough.

3. Zvigayo zvekupedzisira zvine dhizaini yakakasharara inogonesa kucheka zvine simba uye kubudisa chip, zvichikonzera kukurumidza kubviswa kwezvinhu.

4. Inokodzera rough machining yezvinhu zvakasiyana-siyana, kusanganisira simbi, simbi isina tsvina, simbi yakakandwa uye mamwe masimbi ane ferrous uye asina-ferrous simbi.

5. Zvigayo zvekupedzisira zvakagadzirirwa kutsungirira tembiricha yakakwira inogadzirwa panguva yekukasharara, kuderedza deformation yekupisa uye kuve nechokwadi chekuwedzera hupenyu hwematurusi.

6. Zvimwe zvigayo zvekupedzisira zvinogona kunge zvine machira akakosha akadai seTiCN (titanium carbonitride) kana AlTiN (aluminum titanium nitride) kuti awedzere kusakara uye kuwedzera kushandiswa kwechishandiso mumamiriro ezvinhu akaomarara. hupenyu.

7. Zvigayo zvekupedzisira zvinogadzirwa kuti zvipe kugadzikana uye kusimba panguva yekucheka kwehasha, kuderedza kudengenyeka uye kuve nechokwadi chekushanda kwakafanana.

8. Gadzirisai chip kubvisa groove dhizaini uye chip breaker geometry, iyo inobatsira pakubvisa chip inobudirira, inodzivirira chip re-kucheka, uye inovandudza kugadzirisa kushanda.

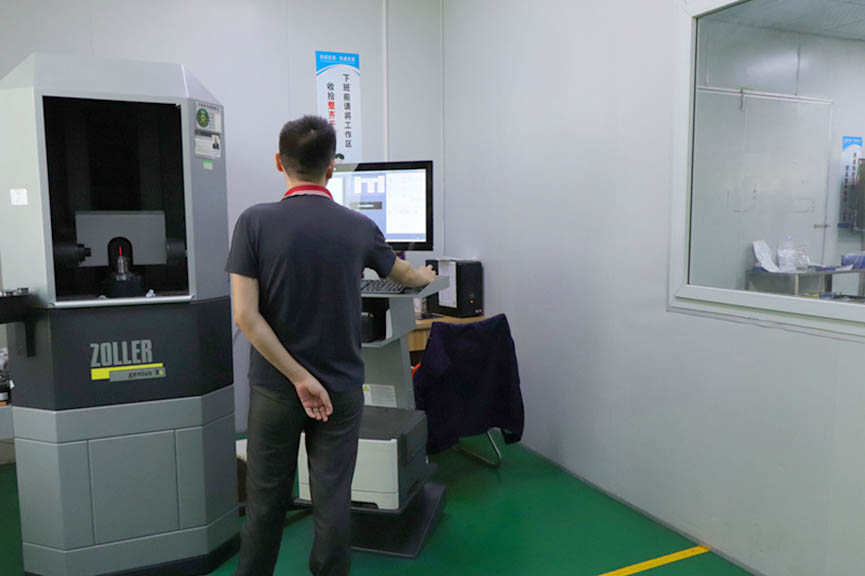

PRODUCT SHOW