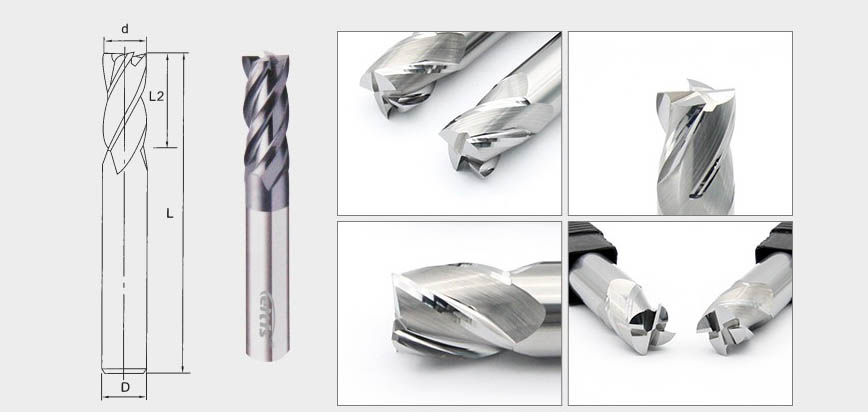

Solid Carbide Square End Mills ye general machining

Features

1. Material: Solid carbide square end mill inogadzirwa kubva kune imwechete chidimbu che carbide zvinhu, izvo zvinogonesa kusimba kwepamusoro uye kuramba kupfeka uye kubvaruka.

2. Kuoma: Carbide inozivikanwa nekuoma kwayo kunoshamisa. Solid carbide square end mill inogona kumira nekumhanya kwekucheka kwakanyanya uye kuchengetedza kupinza kwavo kwenguva yakareba zvichienzaniswa nezvimwe zvinhu.

3. Kunyatsorongeka: Solid carbide square end mill yakagadzirwa nekunyatsofungwa. Ivo vanokwanisa kuburitsa kwakaringana uye kwakachena kucheka, zvichikonzera chaiyo uye yepamusoro-mhando workpieces.

4. Kusiyana-siyana: Zvigayo izvi zvinogona kushandiswa mumhando dzakasiyana-siyana, kusanganisira ferrous uye kwete-ferrous simbi, mapurasitiki, uye macomposites. Izvi zvakasiyana-siyana zvinovaita kuti vakwanise kune dzakasiyana siyana dzemachining application.

5. Kubudirira: Solid carbide square end mills yakagadzirwa nenyere dzakawanda, iyo inowedzera chip evacuation uye kuderedza mikana yekuvhara. Izvi zvinovandudza machining kunyatsoshanda uye kugadzirwa kwese.

6. Kupisa kwekudzivirira: Carbide ine unhu hwakanaka hwekudzivirira kupisa, inobvumira yakasimba carbide square end mills kuti ikwanise kutsungirira kupisa kwakanyanya kunogadzirwa panguva yekucheka mabasa pasina kurasikirwa nekuoma kwavo kana kupinza.

7. Kureba kwenguva refu: Nekuda kwekuoma kwavo kwakanyanya uye kusimba, yakasimba carbide square end mill ine hupenyu hurefu kana ichienzaniswa nemamwe marudzi ekupedzisira mill. Izvi zvinoguma nekutsiviwa kwematurusi mashoma, kuderedza nguva uye mutengo.

8. High kuomarara: Solid carbide end mills ane high rigidity, zvichireva kuti haanyanyi kukotama kana kutsauka panguva yekuita machining. Uku kuomarara kunotungamira kune yakagadziridzwa kucheka kugadzikana uye dimensional kurongeka.

9. Coating options: Solid carbide square end mills inogonawo kuputirwa nemhando dzakasiyana-siyana dzakadai seTiN, TiCN, uye TiAlN, izvo zvinowedzera kuwedzera kushanda kwavo nekuderedza kupesana, kuwedzera hupenyu hwezvishandiso, nekuvandudza chip evacuation.

10. Cutting-edge geometry: Solid carbide square end mill inowanikwa mune akasiyana-siyana ekucheka-kumucheto geometries, seyakatwasuka, helical, uye akasiyana helix dhizaini. Aya ma geometries anopa akasiyana ekucheka maitiro uye anobata kune chaiwo machining zvinodiwa.

Detail display

FACTORY

Zvakanakira

1. Durability: Solid carbide square end mill inozivikanwa nekusimba kwayo kunoshamisa. Carbide zvinhu zvinoshingirira kupfeka uye zvinogona kumira nekumhanya kukuru kwekucheka uye zvinhu zvinokuvadza, zvichikonzera hupenyu hurefu hwematurusi.

2. High Speed Machining: Solid carbide square end mills inogona kunyatsoita high-speed machining operations nekuda kwekuoma kwavo uye kupisa kupisa. Izvi zvinobvumira kuwedzera kubereka uye kupfupika machining nguva.

3. Yakanakisa Chip Evacuation: Nyere dziri pa solid carbide square end mill dzakagadzirirwa optimize chip evacuation. Izvi zvinobatsira kudzivirira chip kuvaka-up uye inova nechokwadi chekucheka kwakatsetseka, kuderedza njodzi yekukuvara kwechishandiso kana kuremara kwechishandiso.

4. Yakanatsiridzwa Yepamusoro Pedzisa: Solid carbide square end mills inobereka yakachena uye yakanyatsochekwa, zvichiita kuti pave nepamusoro pepamusoro pekupedzisira pane workpiece. Izvi zvinobvisa kudiwa kwemamwe maitiro ekupedzisa, kuchengetedza nguva uye mutengo.

5. Versatility: Solid carbide square end mills inokodzera zvakasiyana-siyana zvezvinhu, zvinosanganisira simbi, mapurasitiki, uye macomposites. Izvi zvakasiyana-siyana zvinovaita kuti vakwanise kune akasiyana maindasitiri, kubva kumotokari kusvika kune aerospace.

6. Enhanced Stability: Solid carbide square end mills inoratidzira yakakwirira rigidity, iyo inoderedza kushandiswa kwechishandiso uye inowedzera kugadzikana kwekucheka. Izvi zvinoguma nekuvandudzwa kwedimensional kurongeka uye kuderedzwa mikana yekutyoka kwechishandiso.

7. Precision Machining: Iyo yakapinza yekucheka micheto ye yakasimba carbide square end mill inobvumira kunyatso uye kwakaringana machining. Izvi zvakakosha kune zvikumbiro zvinoda kushivirira kwakasimba uye kuomesesa kutsanangura.

8. Heat Resistance: Solid carbide end mills inogona kumira kutonhora kwakanyanya kunogadzirwa panguva yekugadzira. Izvi zvinodzivirira kupisa kunodzivirira chigadziro kubva pakunyorova kana kurasikirwa nekucheka kwayo, kuve nechokwadi chekushanda kunoenderana.

9. Yakaderedzwa Chishandiso Shanduko: Solid carbide square end mills ine hupenyu hurefu hwematurusi kana ichienzaniswa nezvimwe zvinhu, zvichideredza kudiwa kwekugara kuchinje chishandiso. Izvi zvinotungamira mukuwedzera kugadzirwa kwekuita uye kuderera kuderera.

10. Mutengo-Kushanda: Kunyange zvazvo pakutanga inodhura, yakasimba carbide square end mills inopa kuchengetedza kwemutengo kwenguva yakareba nekuda kwehupenyu hwavo hwekushandisa uye kukwanisa kwepamusoro-soro. Izvi zvinovaita sarudzo inodhura yekugadzira mabasa.

| Chidhaya cheblade (mm) | Kureba kweblade (mm) | Yakazara(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |