Solid Carbide roughing End Mill

Features

1. High material kubviswa mwero: Tungsten carbide roughing end mill yakagadzirwa nenyere shoma kana ichienzaniswa neyakajairwa kupera. Izvi zvinobvumira yakakura chip mutoro uye zvakanyanya hutsinye kucheka chiito, zvichikonzera yakakwirira yekubvisa zvinhu. Iwo akanakira kukurumidza kubvisa huwandu hwakawanda hwezvinhu mukuita roughing.

2. Kuomarara kwepamusoro uye kuramba kupfeka: Tungsten carbide inozivikanwa nekuomarara kwayo kunoshamisa uye kuramba kupfeka. Izvi zvinoita kuti zvigayo zvigayo zvinogadzirwa kubva ku tungsten carbide zvigare zvakasimba, kunyangwe uchigadzira zvinhu zvakaoma sesimbi isina tsvina, alloy simbi, kana simbi yakakandwa.

3. Kugadzira mazino akakora: Zvigayo zvekupedzisira zvine mahombe uye akaparadzana zvakanyanya kana zvichienzaniswa nezvimwe zvigayo. Iyi dhizaini inobatsira kuwana inoshanda chip evacuation uye inodzivirira chip clogging, kuve nechokwadi chekucheka mashandiro.

4. Chip breakers: Mamwe tungsten carbide roughing end mills angave ane chip breaker kana chip splitters pamicheto yekucheka. Aya maficha anobatsira kutyora machipisi marefu kuita zvidimbu zvidiki, zvinogoneka, kusimudzira zvirinani chip evacuation uye kuderedza njodzi yekukuvadzwa kweworkpiece.

5. Kunyanya kupisa kupisa: Kupisa kwepamusoro-kupisa kwe tungsten carbide kunobvumira roughing end mills kuti idzivirire kupisa kunoitwa panguva yekubvisa zvinhu zvinorema. Uku kupisa kupisa kunobatsira kudzivirira deformation yemidziyo kana kutadza kwechishandiso nguva isati yakwana, kuve nechokwadi chehupenyu hurefu hwematurusi.

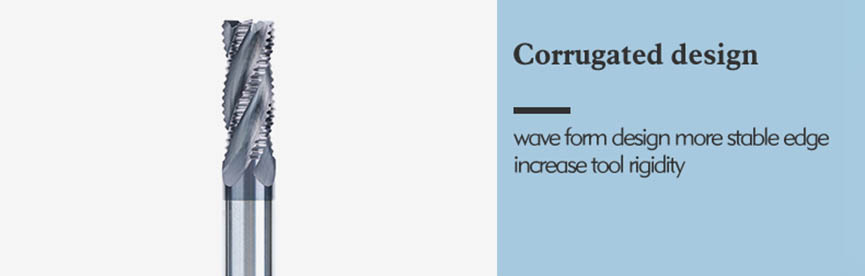

6. Variable helix kana variable pitch design: Zvimwe zvigayo zvinokasharara zvine helix yakasiyana kana dhizaini yepitch design panyere dzawo. Iyi ficha inobatsira kuderedza chatter uye vibration panguva yekucheka, zvichikonzera kugadziridzwa kwepamusoro kupedzisa uye kuwedzera kugadzikana kwechishandiso.

7. Zvigadziro zvekupfekedza: Zvigaro zvinoputika zvinogona kuputirwa nemhando dzakasiyana-siyana, dzakadai seTiAlN, TiCN, kana AlTiN. Aya machira anonatsiridza mashandiro echishandiso nekudzikisa kukweshera, kuwedzera kuyerera kwechip, uye nekuvandudza kupfeka kuramba. Sarudzo yekupfeka yakakodzera zvinoenderana neiyo chaiyo application uye workpiece zvinhu.

8. Kuvaka kwakasimba: Tungsten carbide roughing end mill inovakwa ine yakasimba uye yakasimba chivakwa kuti ikwanise kutsungirira zvinodiwa ne roughing operations. Izvo zvakagadzirirwa kubata masimba makuru ekucheka uye kupa kugadzikana panguva inorema kubvisa zvinhu.

9. Shank options: Tungsten carbide roughing end mills inowanikwa nemhando dzakasiyana-siyana dze shank, kusanganisira shanks dzakatwasuka, Weldon shanks, kana Morse taper shanks. Sarudzo ye shank inotsamira pane mudziyo wemuchina unobata uye izvo chaizvo zvinodikanwa zvemachining setup.

10. Tool geometries: Roughing end mills anogona kuva chaiwo turusi geometries kuti optimize kucheka kuita. Aya ma geometries anogona kusanganisira kuwedzera kwepakati dhayamita, yakasimbiswa yekona radii, kana yakakosha gadziriro yekumusoro yekuwedzera simba rekushandisa uye kuita panguva yekuita roughing.

Detail display

FACTORY