Preminium Hunhu Tungsten Carbide Square End Mill yeSuper Hard Metal

Features

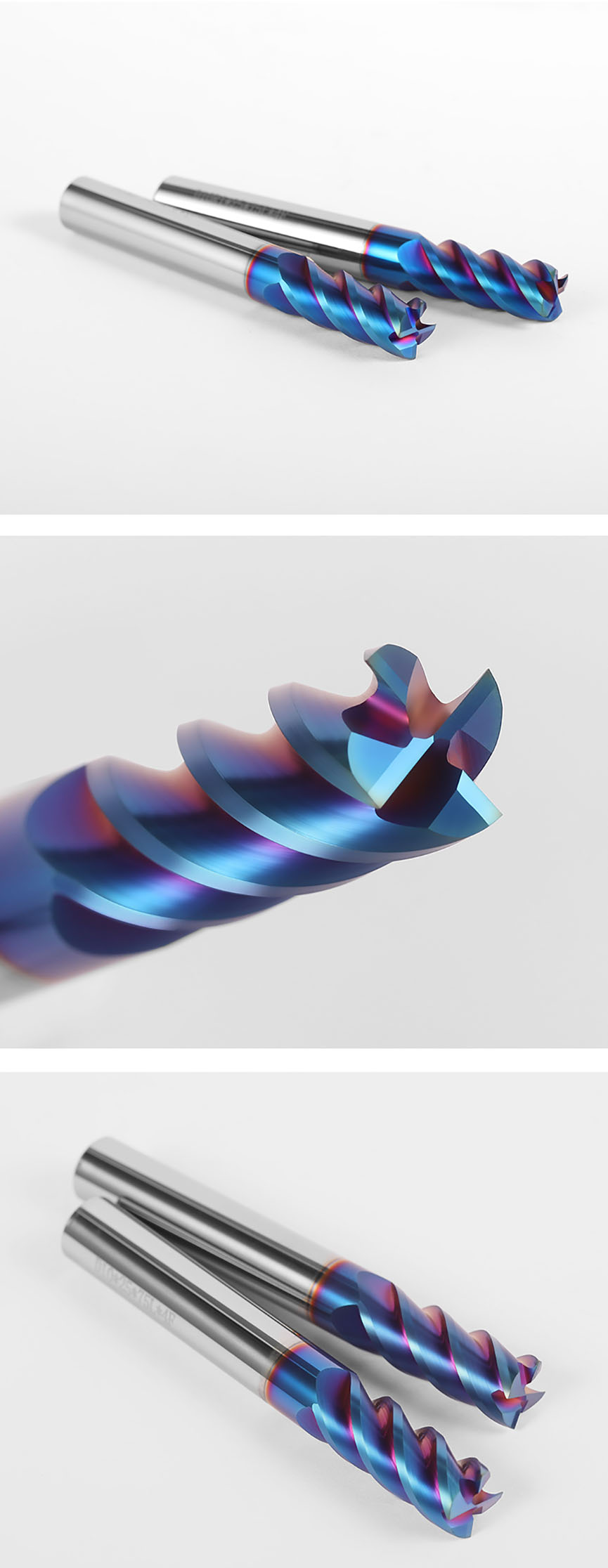

1. Kuwedzeredzwa kuomarara uye kusimba: Iyo tungsten carbide zvinhu inoshandiswa muguyo yekupedzisira inopa kuomarara kwakanakisa uye kusimba, ichiibvumira kutsungirira kukurumidza-kumhanya machining mashandiro uye hupenyu hwematurusi hwakawedzerwa.

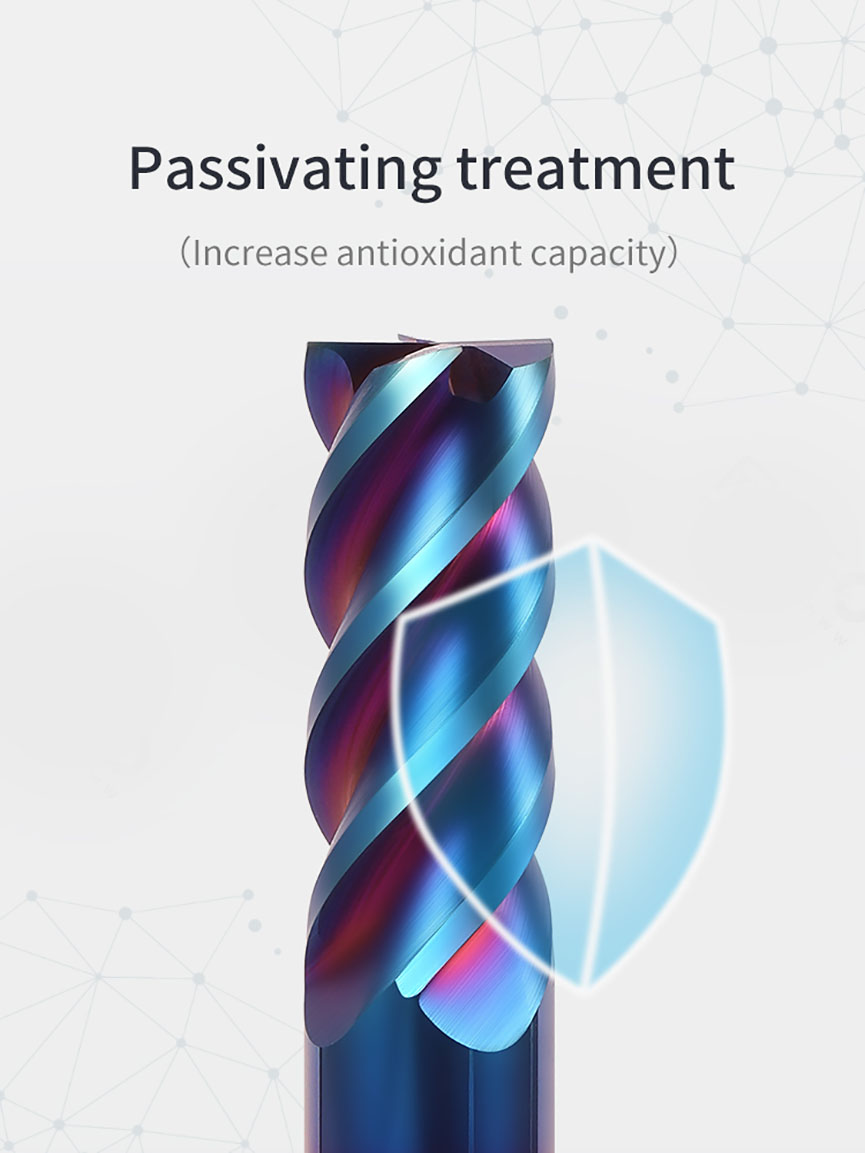

2. Nano blue coating: Iyo nano yeblue coating ifirimu rakatetepa, rakatsetseka rinoiswa kumucheto weguyo uchishandisa advanced coating technologies. Uku kupfekedza kunosimudzira mashandiro echishandiso nekudzikisira kupokana uye kugadzirwa kwekupisa panguva yekucheka, kunatsiridza kubuda kwechip, uye kuramba kupfeka uye ngura.

3. Kuwedzera kukurumidza kucheka: Iyo nano yebhuruu coating inoderedza kukakavara pakati peguyo rekupedzisira uye workpiece, zvichibvumira kukurumidza kucheka. Izvi zvinotungamira kune kuvandudzwa kwechigadzirwa uye kugona mukuita machining mashandiro.

4. Superior heat resistance: Iyo nano blue coating inosimudzira kuguma kweguyo kupisa kwekudzivirira, zvichiita kuti ikwanise kumira kupisa kwakanyanya kunogadzirwa panguva yekucheka. Izvi zvinoderedza deformation yezvishandiso uye zvinowedzera hupenyu hwechishandiso.

5. Yakanakisa kupfeka kuramba: Iyo nano yebhuruu coating inopa kusarudzika kupfeka kusagadzikana, kuderedza chiyero chekupfeka kwechokushandisa uye kuwedzera hupenyu hwayo hwesevhisi. Izvi zvinoguma nekuita kwakafanana kwekucheka uye kuderedzwa nguva yekuchinja kwechishandiso.

6. Kuvandudza chip evacuation: Nzvimbo yakatsetseka ye nano blue coating inokurudzira zviri nani chip evacuation, kudzivirira chip build-up uye kuderedza dambudziko rekuputsika kwechishandiso kana kukanganisa.

7. Kucheka kwakanyatsonaka uye kwakarurama: Kusanganiswa kwepamusoro-soro tungsten carbide zvinhu uye nano blue coating inobvumira kucheka kwakanyatsonaka uye kwakarurama, zvichiita kuti pave nekugadzirisa kwakachena uye kwakatsetseka pane workpiece.

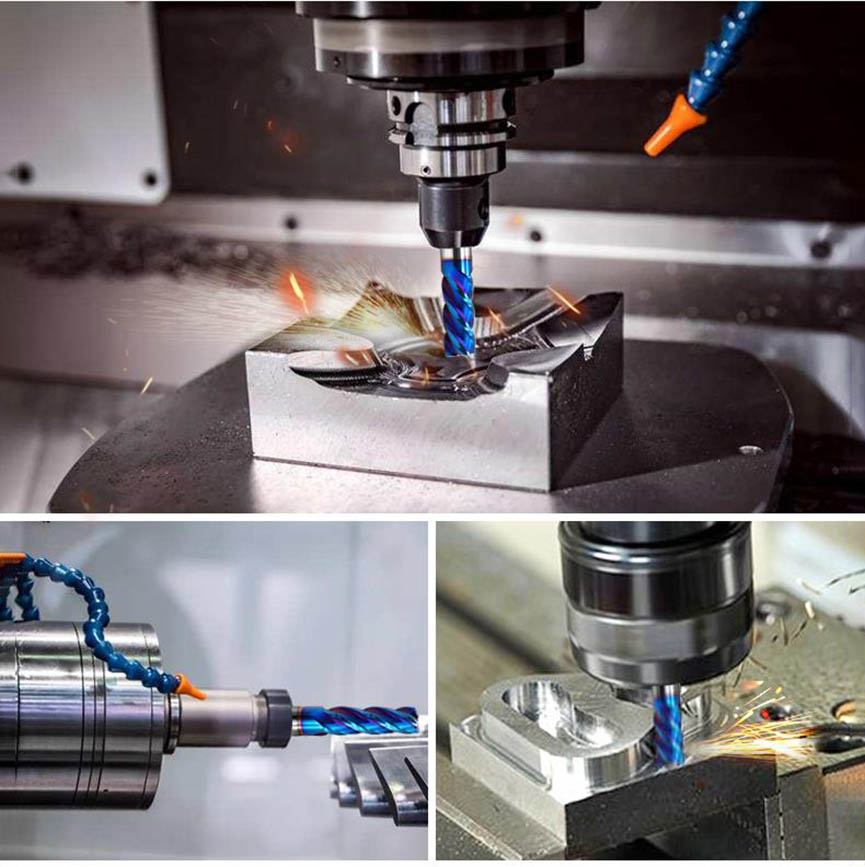

8. Kusiyana-siyana: Tungsten carbide square end mills ine nano blue coating inogona kushandiswa kune zvakasiyana-siyana zvekugadzira, kusanganisira roughing, kupedza, contouring, uye profiling muzvinhu zvakasiyana-siyana zvakadai sesimbi, simbi isina tsvina, aluminium, nezvimwe.

preminium quality tungsten carbide square end mill tsanangudzo

Chigadzirwa dhayagiramu

Zvakanakira

1. Upenyu hwematurusi akakwenenzverwa: Kusanganiswa kwetungsten carbide yemhando yepamusoro uye nano blue coating inowedzera zvakanyanya hupenyu hwechigayo chekupedzisira zvichienzaniswa neshanduro dzisina kuvharwa. Izvi zvinoguma nekudzikiswa kwemitengo yemidziyo uye nekuvandudza goho

2. Kuvandudzwa kwekucheka kukurumidza: Iyo nano yebhuruu coating inoderedza friction uye kupisa chizvarwa panguva yekucheka, zvichibvumira kukurumidza kutema. Izvi zvinobatsira kuwedzera machining kushanda zvakanaka uye kuderedza nguva yekutenderera.

3. Kuwedzera kupfeka kuramba: Iyo nano yebhuruu coating inosimudzira kupera kweguyo kusakara, ichipa dziviriro kubva pakupwanya uye kuwedzera hupenyu hwechishandiso. Izvi zvinoreva kushoma kazhinji maturusi shanduko uye kuderedzwa nguva yekudzikira.

4. Superior surface finish: Iyo nano blue coating inoderedza kuvakwa-kumucheto uye inoderedza mauto ekucheka, zvichiita kuti pave nekugadzirisa uye kunyatsojeka pamusoro pebasa rekushanda. Izvi zvinonyanya kubatsira kune zvikumbiro zvinoda kukwirira kwepamusoro.

5. Chip evacuation uye inotonhorera kunyatsoshanda: Iyo nano yebhuruu coating inovandudza chip kuyerera uye inotonhorera kugovera, kudzivirira chip clogging uye kuve nechokwadi kunoshanda kupisa kupisa. Izvi zvinobatsira kuchengetedza kuita kwakanaka kwekucheka uye kuderedza njodzi yekutadza kwechishandiso.

6. Corrosion resistance: Iyo nano blue coating inopa chipingamupinyi chinodzivirira kubva pakuora, kuwedzera kusimba kweguyo yekupedzisira uye kuderedza mukana wekutadza kukasika nekuda kwekuparara kwemakemikari.

7. Kusiyana-siyana mumashandisirwo ekugadzira: Premium quality tungsten carbide square end mills ine nano blue coating inogona kushandiswa muzvinhu zvakasiyana-siyana, zvinosanganisira simbi isina tsvina, simbi yakaoma, simbi yakakandwa, uye simbi isina-ferrous. Iwo akakodzera roughing, kupedzisa, uye contouring mashandiro, achipa kuchinjika mumachining application.

8. Kuvandudzwa kwechishandiso kugadzikana: Iyo nano yebhuruu coating inobatsira kuderedza kuzununguka uye kunatsiridza kugadzikana kwechishandiso panguva yekucheka, zvichikonzera kuvimbika kwemaitiro epamusoro uye kuvandudzwa kwedimensional.

9. Makomborero ezvakatipoteredza: Kushandiswa kwepamusoro-soro yekuguma kweguyo ine nano blue coating inogona kuderedza kucheka zvigadziro, zvakadai sekucheka masimba uye kukurumidza kucheka. Izvi zvinogona kutungamira mukuchengetwa kwesimba uye kuderera kwekushandisa zviwanikwa, zvichibatsira kune yakasvibira uye inoenderera mberi machining process.

| Chidhaya cheblade (mm) | Kureba kweblade (mm) | Yakazara(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |