Iyo Precision Edge: Kuvhura Simba reTCT Saw Blades muMazuvano Kucheka Zvikumbiro

Iyo Chiremba Yekuvhiya: Sei TCT Technology Inoshandura Kucheka

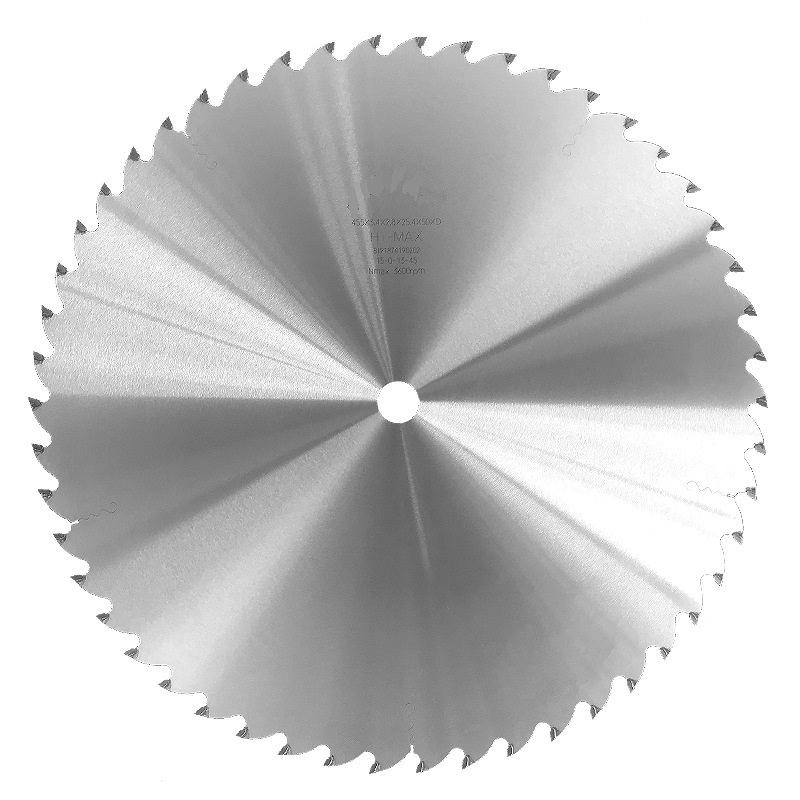

Tungsten Carbide Tipped (TCT) mashizha ekuona anomiririra iyo yepamusoro yekucheka tekinoroji, kusanganisa kurongeka kwekuvhiya nekusimba kwemaindasitiri. Kusiyana nemablades akajairwa, TCT inosanganisa macro-grain tungsten carbide mazino - iro rakaomesesa zvinhu kirasi pfupi yedhaimondi - yakanyungudutswa kana kusungirirwa pamiviri yesimbi yakasimba. Iyi hybrid dhizaini inopa kuita kusingaenzaniswi pamatanda, simbi, macomposites, uye zvakakosha zvinhu, zvichiita kuti ive shasha isingapokane mumashopu ehunyanzvi uye zvimiro zveindasitiri pasi rese.

Core Injiniya: Iyo Anatomy yePeak Performance

1. Advanced Material Science

- Tungsten Carbide Mazino: Yakagadzirwa neYG8-giredhi carbide kana cobalt-yakaiswa akasiyana, aya matipi anochengetedza kupinza 8-10x kureba kupfuura HSS blades, kunyangwe kana uchicheka abrasive hardwoods (oki, teak) kana simbi isina tsvina.

- Anti-Friction Coatings: PVD (Physical Vapor Deposition) machira pamashizha senge NYX SS akatevedzana anoderedza kupisa kwekuwedzera ne40%, kudzivirira kunamatira kwezvinhu, uye kuwedzera blade hupenyu 3x mukucheka simbi isina tsvina.

- Shock-Absorbing Cores: High-fracture-toughness steel body (HRC 65) inodzivirira warping panguva yekushanda kwe-high-torque, yakakosha pasimbi inotonhora inocheka apo tembiricha inodarika 600°F.

2. Geometric Innovations

- Mazita eZino:

- Conical Scoring Mazino: Kune laminate/veneer mapaneru, mazino econical anogadzira zvidimbu zvisina zvidimbu ne pre-scoring surface.

- Anti-Vibration Dhizaini: Spiral nyere (15-25 ° helix angles) mumatanda anogonesa kutsetseka kwechip evacuation, kuderedza ruzha ne15 dB uye kubvisa workpiece vibration.

- Oblique Clamping: Patented 45–90° screw angles mumablade akasungirirwa anowedzera kugadzikana, kuderedza kutama kwemazino panguva yekucheka simbi inorema.

3. Precision Bancing

- Laser-calibrated tensioning inovimbisa kuzununguka ≤0.1mm, kunyangwe pa660mm madhayamita. Izvi zvinodzivirira kutsauka pakucheka machubhu akakora-akavezwa nesimbi isina tsvina, kuchengetedza kushivirira kwakachekwa mukati me ± 0.2mm.

Performance Advantages: Kupfuura Kumhanya uye Hurefu Hwehupenyu

- Material Versatility

Imwe NYX yakatevedzana blade inoshandura zvisina mutsetse pakati:- Simbi: Simbi yekugadzira, aluminium (Bosun MAG350120L blades akacheka aluminium pa3,000 RPM), uye machubhu asina tsvina.

- Wood Composites: Hardwoods, MDF, uye phenolic laminates pasina kubvarura-kunze.

- Kubudirira Kweupfumi

- Yakawedzerwa Hupenyu: 2–3x yakareba nguva yekumhanya kupfuura mablades akajairika-20-24 maawa pared sandalwood vs. 8 maawa ecarbon steel .

- Kuchengetedza Kwemagetsi: Yakagadziridzwa zino geometry inoderedza kudhirowa kwemagetsi ne18% mukutonhora-kucheka maapplication.

- Pamusoro Hunhu & Kuchengetedzeka

- Burr-Yemahara Edges: Kutonhora-kucheka tekinoroji inochengeta maworkpiece achitonhorera, kudzivirira kukanganiswa kwemafuta uye kubvisa kupedzisa kwechipiri.

- Kudzora Dust: Spiral nyere dhizaini inobata 95% yemachipisi ehuni, ichidzikisa mhepo.

Kushandisa-Chaiyo Mhinduro: Kufananidza Blades kune Mabasa

Industrial Metalworking

- Thick-Section Steel: NYX DS PVD blades (660mm) ine 180 mazino akacheka mabheti akasimba pa60-380 m / min. Kutonhora kwemvura kunosungirwa.

- Stainless Tubing: CHAOS akatevedzana mablades (400mm) anoshandisa mana-nyere TCT mazino kucheka machubhu akatetepa-ane madziro (5mm min) pasina kudonha.

Woodworking & Composites

- Hardwood Bandsawing: TCT mabhandeji anocheka muoki pa25 m/s—kaviri kumhanya kwekabhoni blades — aine zero kutsva.

- CNC Machining: 25 ° spiral-angle router bits inogonesa 2x inokurumidza kudya mitengo muMDF kuveza vs.

Specialty Cutting

- Aluminium Kugadzirwa: 120-mazino mazino (Bosun MAG350120L) kudzivirira galling kuburikidza nealternating bevel mazino.

- Laminated Panels: Anochinjika zvibodzwa mablades anogadzira veneer-hushamwari kerfs dzakatetepa se2.0mm.

Tafura: TCT Blade Selection Guide by Material

| Material Type | Blade Series | Key Specs | Optimal Feed Rate |

|---|---|---|---|

| Simbi isina ngura | NYX SS PVD 6 | 180 mazino, Ø225-660mm | 40–80 m/min |

| Hardwood | TCT Spiral 5 | 15–25° helix, 0.45x core ratio | 8–12 m/min |

| Aluminium | Bosun MAG 8 | 120 mazino, Ø350mm | 25–40 m/min |

| Concrete/Re-bar | SDS Plus 2 | 4-nyere, YG8 carbide matipi | 10–150 m/min |

Kukwirisa Blade Hupenyu: Maintenance Protocols

- Coolant Discipline: Mvura-soluble emulsions inosungirwa yekucheka simbi; kucheka kwakaoma chete kunobvumirwa huni pasi pe20mm ukobvu.

- Kuongorora Zino: Tarisa kuti carbide yakatsemuka maawa makumi mashanu ega ega ekushanda-chinja kana kucheka kwakapfuura 0.3mm.

- Kuchengetedza: Rembera wakatwasuka munzvimbo dzinodzorwa nemamiriro ekunze; humidity> 60% inomhanyisa simbi ngura.

Iyo Ramangwana Edge: Akangwara Blades uye Indasitiri 4.0

Inotevera-gen TCT blades inonyudza RFID machipi kuteedzera kupera kwemazino uye maawa ekucheka, kuwiriranisa neCNC masisitimu ekurodza otomatiki chenjedzo. Zvichakadaro, nano-layered carbide coatings (pasi pekuvandudzwa) inovimbisa 5x hupenyu mukucheka titanium.

Mhedziso: Kururamisa seMaitiro

TCT yakaona mablades achipfuura basa rawo sematurusi ekucheka chete - iwo mainjiniya masisitimu anobatanidza simbi, geometry, uye simba. Kunyangwe kuchekerera tubing isina tsvina ine micron-level kurongeka kana kuveza hardwood nehunyanzvi finesse, vanounza kunyatsoshanda. Kune vanogadzira vanotsvaga zero-tsvina yekugadzira kana matanda vanoda kugarwa-yakagadzirira kupera, kuisa mari mukushandisa-chaiyo TCT tekinoroji haisi sarudzo-ndiyo nheyo yemakwikwi ehunyanzvi.

Nguva yekutumira: Jul-20-2025