Morse Taper Shank HSS End Mills

Features

1. Morse Taper Shank: Chigayo chekupedzisira chine shank yakagadzirirwa kukwana muMorse Taper spindle. Iyo Morse Taper sisitimu inobvumira kuchengetedzwa uye kwakaringana kukwira kwechigayo chekupedzisira mumushini wekugaya.

2. High-Speed Steel (HSS): HSS imhando yesimbi yekushandisa inowanzoshandiswa mukucheka midziyo. HSS end mill inozivikanwa nekuomarara kwayo, kudzivirira kupisa, uye kugona kumirisana nekumhanya kukuru kwekucheka. HSS end mills inokodzera zvakasiyana-siyana zvezvinhu, zvinosanganisira kabhoni simbi, alloy simbi, Stainless simbi, uye non-ferrous simbi.

3. Nyere: Chigayo chekupedzisira chichava nenyere dzakawanda pakureba kwayo. Nyere ndiyo helical kana kuti yakatwasuka grooves pamusoro peguyo rekupedzisira. Nyere dzinobatsira mukubvisa chip uye inopa mipendero yekucheka yekubvisa zvinhu. Huwandu hwenyere hunogona kusiyana zvichienderana nekushandisa, nesarudzo dzakajairika dziri 2, 4, kana 6 nyere.

4. Cutting Edge Geometry: HSS end mills inouya mumhando dzakasiyana-siyana dzekucheka geometries, dzakadai sesquare end, ball nose, kona radius, kana chamfer. Imwe neimwe geometry inokodzera chaiyo milling mashandiro uye inodiwa nzvimbo inopera.

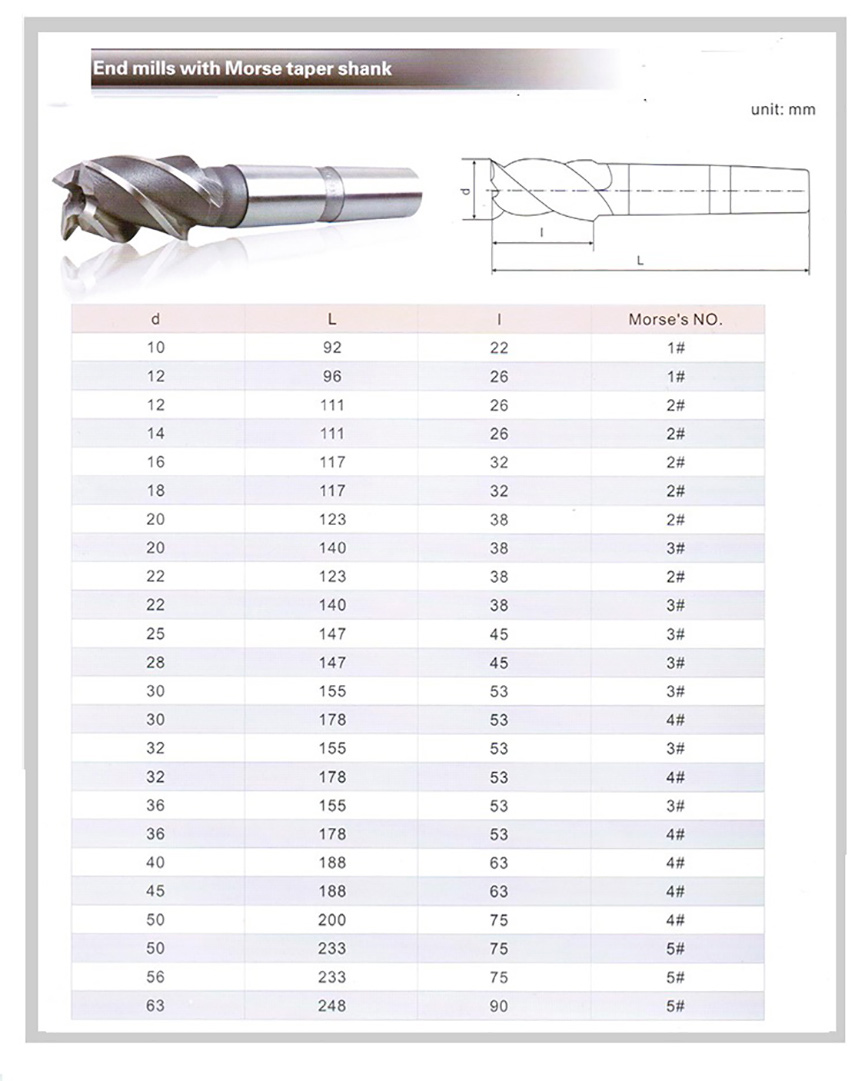

5. Kureba Kwese uye Kureba Kwenyere: Urefu hwese hunoreva hurefu hwese hweguyo rekupedzisira, kubva kumucheto wekucheka kusvika kumagumo eshank. Kureba kwenyere kunoreva kureba kwechikamu chekucheka kana nyere. Hurefu hwakasiyana huripo kuti hugadzirise hudzamu hwakasiyana hwekugaya uye zvinodiwa zvekubvisa.

6. Coating Options: HSS end mills inogonawo kuuya nemhando dzakasiyana-siyana dzekuputira seTiN, TiCN, kana TiAlN. Aya mabhanhire anopa kuvandudza kupfeka kuramba, kuwedzera hupenyu hwezvishandiso, uye kuita zvirinani mukumhanya-mhanya kana kudziya kwepamusoro-tembiricha yekucheka zvikumbiro.

7. Standard Sizes: Morse Taper shank HSS end mills inowanikwa muhukuru hunoenderana neMorse Taper zita (MT1, MT2, MT3, nezvimwewo). Aya saizi anovimbisa kukodzera kwakaringana uye kuenderana nemichina yekugaya nemaspindle.

fekitari

Morse taper shank HSS end mill tsanangudzo

Zvakanakira

1. Chengetedza uye Yakarurama Kukwira: The Morse Taper shank inopa yakachengeteka uye yakanyatsokodzera inopindirana mu spindle, kuderedza kumhanya uye kuve nechokwadi chekucheka kwakaringana. Izvi zvinobatsira kuchengetedza kuenderana kwedimensional kurongeka uye kupera kwepamusoro muzvikamu zvakagadzirwa.

2. Versatility: Morse Taper shank HSS end mills anowanikwa muhukuru hwakasiyana-siyana uye geometries, zvichiita kuti dzive dzakakodzera kwakasiyana-siyana kugaya uye mhando dzezvinhu. Izvi zvakasiyana-siyana zvinobvumira huwandu hwakawanda hwemashandisirwo pasina kudiwa kweakawanda maturusi setups.

3. Durability uye Heat Resistance: HSS magumo emagetsi anozivikanwa nokuda kwekuoma kwavo uye kudzivisa kupisa. Vanogona kumira kumhanya kwekucheka kwakanyanya uye kuchengetedza kuita kwavo kwekucheka kunyangwe pasi pekupisa kwakanyanya kunogadzirwa panguva yekugadzira. Uku kusimba kunoshandura hupenyu hurefu hwematurusi, kuderedza kuwanda kwekutsiviwa kwechishandiso uye nguva yekudzikira mukuita machining.

4. Inodhura-Inoshanda: HSS magumo emagetsi anowanzo wedzera mari-inoshanda kana ichienzaniswa nezvimwe zvepamusoro-zvishandiso zvishandiso, senge carbide. HSS yekupedzisira zvigayo zvinopa chiyero chakanaka pakati pekuita uye mutengo, zvichiita kuti ive sarudzo yakakodzera kune yakaderera vhoriyamu machining, zvinhu zvinonetsa, kana maapplication ane zvishoma zvinoomesesa zvinodiwa.

5. Kugarisana: Morse Taper shank HSS end mill yakagadzirirwa kuenderana neyakajairwa Morse Taper spindles anowanzo kuwanikwa mumilling michina. Kuenderana uku kunorerutsa kuseta kwechishandiso, kunoderedza kudiwa kwemamwe maadapter, uye kunobvumira kuchinjika kuri nyore pakati pezvishandiso zvakasiyana.

6. Kupinzazve Kugona: HSS magumo emagetsi anogona kurodzwa nyore nyore, kuwedzera hupenyu hwavo hunobatsira uye kuderedza mutengo wekushandisa nekufamba kwenguva. Nekugadzirisa kwakaringana uye kurodza, HSS yekupedzisira chigayo inogona kuunza kushanda kwakaringana uye kukosha pamusoro peakawanda machining kutenderera.

7. Wide Material Compatibility: HSS end mills inogona kunyatsogadzira zvinhu zvakasiyana-siyana, kusanganisira carbon steel, alloy steel, Stainless steel, cast iron, non-ferrous metals, uye mapurasitiki. Izvi zvakasiyana-siyana zvinoita kuti vakwanise kune akasiyana maindasitiri uye maapplication.