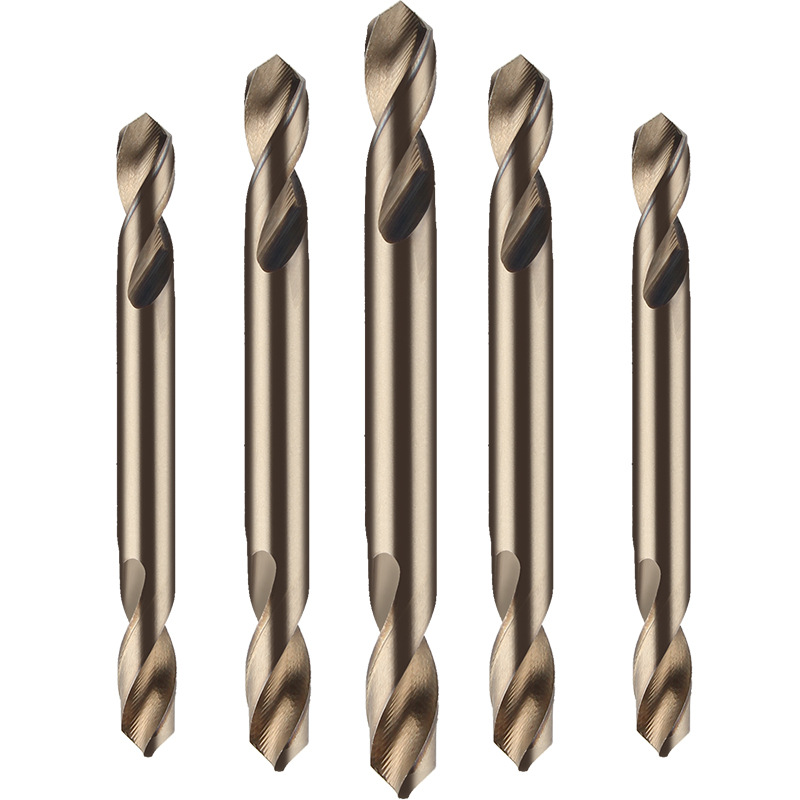

HRC55 bhora mhino Tungsten Carbide End Mill

Features

Iyo HRC55 bhora mhino carbide end mill yakagadzirirwa kumuchina zvinhu zvinosvika makumi mashanu neshanu HRC (Rockwell C) uye inoratidzira bhora mhino geometry yakakodzera kutenderedza uye profiling application. Zvimwe zvakakosha zveHRC55 bhora mhino carbide end mill zvinosanganisira:

1. Material: Yakagadzirwa ne tungsten carbide yakasimba, nehupamhi hwekuoma uye kupfeka kusagadzikana, yakakodzera kucheka zvinhu nekuoma kusvika ku55 HRC.

2. Bhora musoro geometry inogonesa yakatsetseka, yakanyatso dhizaini, contouring uye 3D machining, ichigonesa kusikwa kwepamusoro-chaiyo yakatenderedzwa kana sculpted nzvimbo.

3. Kupfekedza: Kazhinji yakaputirwa nemabhanhire epamusoro akadai seTiAlN kana AlTiN kuti awedzere kupisa, kuderedza kukwesha, uye kunatsiridza kusakara, nekudaro kuwedzera hupenyu hwematurusi nekuvandudza kushanda.

4. Chip kubviswa: Chip kubvisa groove dhizaini uye chip yekubvisa basa yakagadziridzwa kuti ibudirire kubvisa machipisi panguva yekucheka, kudzivirira chip kuunganidza, uye kuve nechokwadi chekugadzirisa mashandiro.

5. High-speed machining: Nekuda kwekubatanidzwa kwezvinhu zvecarbide uye zvipfeko zvakakosha, kushandiswa kwepamusoro-kumhanya kunogoneka, nekudaro kunovandudza kubereka uye kupera kwepamusoro.

6. Precision uye Surface Pedzisa: Yakagadzirirwa kupa yakanyatsojeka uye yepamusoro yepamusoro yepamusoro, ichiita kuti ive yakakodzera kune zvikumbiro apo kunyatsojeka uye pamusoro aesthetics inokosha.

7. Kusiyana-siyana: Yakagadzirwa kuti ienderane nezvinhu zvakasiyana-siyana, zvinosanganisira simbi yakaomeswa, simbi isina tsvina uye mamwe alloys, ichipa versatility mune zvakasiyana-siyana zvekugadzira machining applications.

PRODUCT SHOW